The Importance of Crankshaft Engines in the Diesel Industry

The crankshaft engine is a fundamental component of any diesel engine, serving as the backbone that converts linear motion into rotational energy. This intricate process is crucial for the performance, efficiency, and overall functionality of diesel-powered vehicles and machinery. In this comprehensive guide, we will explore everything there is to know about crankshaft engines, from their components and functions to how they impact the performance of diesel engines.

Understanding the Crankshaft: The Heart of Engine Performance

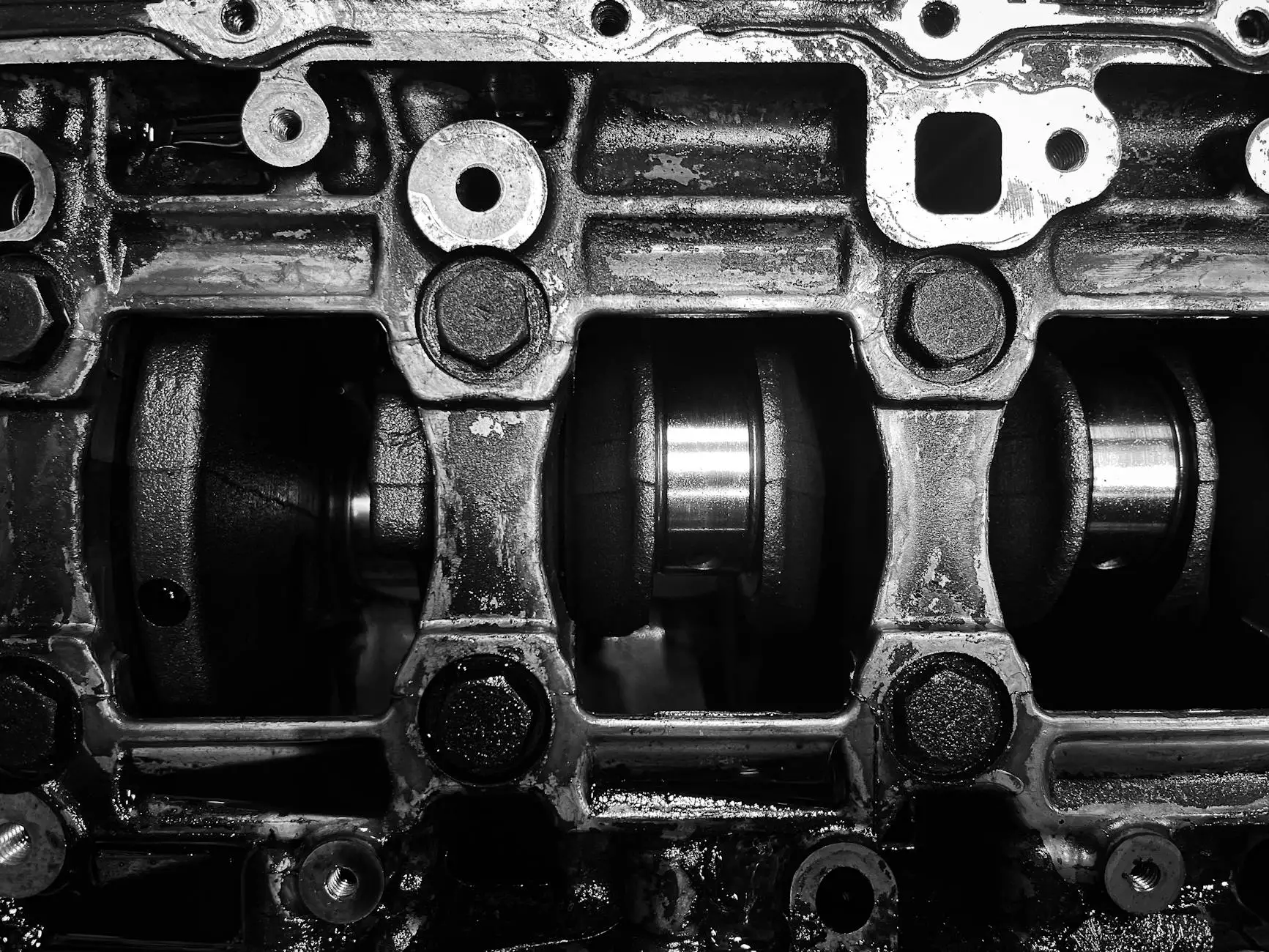

The crankshaft is essentially a rotating shaft that transforms the reciprocating motion of the pistons into rotational motion, which ultimately drives the vehicle's wheels or powers machinery. The efficiency of this conversion is vital and directly affects the engine's performance.

Components of a Crankshaft Engine

The design of a crankshaft engine includes several key components:

- Crankpins: These are the parts where the connecting rods attach to the crankshaft. They play a vital role in transferring energy.

- Main Bearings: These bearings support the crankshaft and allow it to rotate smoothly within the engine block.

- Counterweights: Essential for balancing the engine, counterweights help reduce vibrations generated by the engine's operation.

- Crankshaft Pulley: This component connects the crankshaft to various engine accessories, helping operate systems such as the alternator and water pump.

- Flywheel: Attached to one end of the crankshaft, the flywheel helps maintain momentum and smooth out the power delivery from the engine.

Types of Crankshafts

There are several types of crankshafts used in diesel engines, each with its specific application and advantages:

- Cast Iron Crankshafts: These are common due to their durability and cost-effectiveness, making them suitable for most diesel applications.

- Steel Crankshafts: Known for their strength and resistance to deformation, these are often used in high-performance engines.

- Billet Crankshafts: These are machined from solid steel, offering excellent performance and customization options for racing and high-torque applications.

The Role of Crankshaft Engines in Diesel Performance

The performance of a diesel engine is directly influenced by the design and functionality of its crankshaft. Here’s how:

1. Power Delivery

Effective power delivery is crucial for any engine. A well-designed crankshaft optimizes the timing and smoothness of the power generated by the pistons. This efficiency leads to:

- Improved Fuel Efficiency: The smoother the power delivery, the less fuel is wasted during combustion.

- Enhanced Acceleration: A balanced and well-crafted crankshaft reduces lag, resulting in quicker acceleration.

2. Engine Longevity

Engines with quality crankshafts tend to have a longer lifespan. Here's why:

- Reduced Vibrations: Effective counterweights and proper balancing minimize vibrations, which can lead to premature engine wear.

- Less Heat Generation: Smooth operation results in less heat, preventing overheating and extending engine life.

3. Performance Under Load

Diesel engines are often used in heavy-duty applications, where load and stress are significant factors. A robust crankshaft allows for:

- Increased Torque: Properly engineered crankshafts can handle high torque outputs, which is essential for vehicles such as trucks and machinery.

- Stable Operation: Even under heavy load conditions, a high-quality crankshaft ensures stable engine operation.

Choosing the Right Crankshaft for Your Diesel Engine

Selecting the right crankshaft is crucial for optimizing your engine's performance. Consider the following factors:

1. Application Requirements

Determine what the primary use of the engine will be. For instance:

- If you are building a racing engine, consider a billet crankshaft for its superior performance characteristics.

- If the engine is for a trucking application, invest in a durable cast iron crankshaft that can handle heavy loads.

2. Material Quality

Understand the material properties and their impact on performance:

- Steel: Offers strength and performance for high-compression engines.

- Cast Iron: Great for everyday applications due to its resilience and cost-effectiveness.

3. Manufacturer Reputation

Always opt for crankshafts from reputable manufacturers. High-quality parts ensure reliability and performance. A trusted supplier, such as client-diesel.com, provides verified engine parts that cater specifically to the diesel industry.

Maintenance of Crankshaft Engines

Maintaining a diesel engine’s crankshaft is critical to ensure its longevity and performance. Here are some essential maintenance tips:

Regular Oil Changes

Using high-quality oil reduces friction and wear on the crankshaft bearings, allowing for smoother engine operation. Regular oil changes are essential for:

- Removing contaminants that could cause engine wear.

- Improving the overall efficiency of the engine.

Monitor Engine Performance

Keep track of any changes in performance. Common signs that your crankshaft may need attention include:

- Unusual vibrations when the engine is running.

- Declining fuel efficiency.

- Unusual noises coming from the engine.

Use Quality Parts for Repairs

When replacing parts, ensure that you use high-quality components. For example, sourcing your crankshaft and related parts from a dedicated supplier such as client-diesel.com ensures that your engine functions optimally.

The Future of Crankshaft Technology

The advancement of technology has paved the way for innovations in crankshaft design and manufacturing. Some trends to watch for include:

1. Lightweight Materials

The use of materials such as carbon fiber and advanced alloys is becoming more common, offering reduced weight without sacrificing strength.

2. CNC Machining

Computer Numerical Control (CNC) machining allows for incredibly precise crankshaft manufacturing, improving balance and reducing the imperfections that can lead to vibrations.

3. Enhanced Balancing Techniques

Innovative balancing techniques help optimize crankshaft performance, leading to smoother operation and improved efficiency.

Conclusion

In summary, the crankshaft engine plays a pivotal role in the performance and longevity of diesel engines. Understanding its components, functions, and impact on engine performance enables diesel engine owners and enthusiasts to make informed decisions about maintenance, repair, and upgrades. As the industry continues to innovate, staying updated on advancements will ensure that you leverage the best practices and technology for optimal engine performance.

Investing in quality crankshafts from reputable suppliers like client-diesel.com not only enhances performance but also ensures reliability, efficiency, and longevity of your diesel engines.